For a supply greater than 5v, a different MOSFET configuration must be used to get full rail-to-rail output. The MOSFETs must be turned on individually.

PUSH-PULL USING MOSFETS

PUSH PULL USING MOSFETS

The circuit above sinks up to 35A via the N-channel MOSFET and delivers about 18Amp via the P-channel MOSFET. Input A must rise quickly to prevent the MOSFET heating up during the turning-on period. Input A must rise to at least 4v to guarantee the MOSFET turns ON.

Input B must rise above 0.65v to turn the transistor ON. The voltage on the collector of the transistor will fall and this will provide a gate-to-source voltage for the P-channel MOSFET.

Both inputs must not be HIGH at the same time as this will turn ON both MOSFETs and create a short-circuit on the power rail.

The circuit above is much more complex than meets the eye.

To turn on the top N-channel MOSFET, the gate must be taken at least 3v higher than the source because it is a SOURCE FOLLOWER (similar to an EMITTER FOLLOWER). This is equal to Vin + 3v.

How does pin HG get this high voltage?

It gets it from a voltage doubling circuit made up of the 0.33u, high speed diode D1 and an oscillator in the chip.

The circuit is a buck converter and will reduce any supply voltage to a lower voltage with very high efficiency. It allows a small 'packet of energy' to flow to the Vout terminal via the inductor L1 and this percentage determines the Vout voltage.

Here is an audio amplifier using PUSH PULL mode to drive a speaker:

The top two transistors are in push-pull mode to turn the P-channel MOSFET on and off very quickly. They speed up the incoming waveform and prevent the MOSFET generating heat during the turning-on process.

The two lower transistors do the same thing.

The diodes and resistors connected to the input form a voltage-divider to correctly bias the push-pull transistors.

H-BRIDGE

An H-Bridge can be designed using MOSFETs:

Input A HIGH, Input D HIGH - forward rotation

Input B HIGH, Input C HIGH - reverse rotation

Input A HIGH, Input B HIGH - not allowed

Input C HIGH, Input D HIGH - not allowed

The H-Bridge can be designed with two more transistors so that only two input lines are needed.

PWM MOTOR SPEED CONTROLLER

Here is a circuit from a 12v drill. The MOSFET will deliver up to 30Amps.

The frequency of the oscillator is in the range 550Hz to about 6.5kHz, with an off period of about 2.6us.

Tensorflow cheat sheet pdf.

PWM 12v CORDLESS DRILL MOTOR CONTROLLER

3-LED CHASER

This circuit let's you see how a FET turns on and how it works.

Remove the connections to the gate of the first FET and the LED will start to illuminate.

The gate will start to get a charge on it and the FET will turn on.

Place a 1M between gate and 0v and the FET will turn off.

This shows the sensitivity of the gate. The charge on the gate must be removed for the FET to turn OFF.

This circuit will show how the FET turns ON slowly as the voltage on the gate increases and turns OFF slowly as the voltage drops:

WHY MOSFETs FAIL

There are quite a few possible causes for device failures, here are a few of the most important reasons:

MOSFETs have very little tolerance to over-voltage. Damage to devices may result even if the voltage rating is exceeded for as little as a few nanoseconds. MOSFET devices should be rated conservatively for the anticipated voltage levels and careful attention should be paid to suppressing any voltage spikes or ringing.

- Prolonged current overload:

High average current causes considerable thermal dissipation in MOSFET devices even though the on-resistance is relatively low. If the current is very high and heatsinking is poor, the device can be destroyed by excessive temperature rise. MOSFET devices can be paralleled directly to share high load currents.

- Transient current overload:

Massive current overload, even for short duration, can cause progressive damage to the device with little noticeable temperature rise prior to failure.

- Shoot-through - cross conduction:

If the control signals to two opposing MOSFETs overlap, a situation can occur where both MOSFETs are switched on together. This effectively short-circuits the supply and is known as a shoot-through condition. If this occurs, the supply decoupling capacitor is discharged rapidly through both devices every time a switching transition occurs. This results in very short but incredibly intense current pulses through both switching devices.

The chances of shoot-through occurring are minimised by allowing a dead time between switching transitions, during which neither MOSFET is turned on. This allows time for one device to turn off before the opposite device is turned on.

- No free-wheel current path:

When switching current through any inductive load (such as a Tesla Coil) a back EMF is produced when the current is turned off. It is essential to provide a path for this current to free-wheel in the time when the switching device is not conducting the load current.

This current is usually directed through a free-wheel diode connected anti-parallel with the switching device. When a MOSFET is employed as the switching device, the designer gets the free-wheel diode 'for free' in the form of the MOSFETs intrinsic body diode. This solves one problem, but creates a whole new one..

- Slow reverse recovery of MOSFET body diode:

A high Q resonant circuit such as a Tesla Coil is capable of storing considerable energy in its inductance and self capacitance. Under certain tuning conditions, this causes the current to 'free-wheel' through the internal body diodes of the MOSFET device. This behaviour is not a problem in itself, but a problem arises due to the slow turn-off (or reverse recovery) of the internal body diode.

MOSFET body diodes generally have a long reverse recovery time compared to the performance of the MOSFET itself.

This problem is usually eased by the addition of a high speed (fast recovery) diode. This ensures that the MOSFET body diode is never driven into conduction. The free-wheel current is handled by the fast recovery diode which presents less of a 'shoot-through' problem.

If the MOSFET gate is driven with too high a voltage, then the gate oxide insulation can be punctured rendering the device useless. Gate-source voltages in excess of +/- 15 volts are likely to cause damage to the gate insulation and lead to failure. Care should be taken to ensure that the gate drive signal is free from any narrow voltage spikes that could exceed the maximum allowable gate voltage.

- Insufficient gate drive - incomplete turn on:

MOSFET devices are only capable of switching large amounts of power because they are designed to dissipate minimal power when they are turned on. It is the responsibility of the designer to ensure that the MOSFET device is turned hard on to minimise dissipation during conduction. If the device is not fully turned on then the device will have a high resistance during conduction and will dissipate considerable power as heat. A gate voltage of between 10 and 15 volts ensures full turn-on with most MOSFET devices.

- Slow switching transitions:

Little energy is dissipated during the steady on and off states, but considerable energy is dissipated during the times of a transition. Therefore it is desirable to switch between states as quickly as possible to minimise power dissipation during switching. Since the MOSFET gate appears capacitive, it requires considerable current pulses in order to charge and discharge the gate in a few tens of nano-seconds. Peak gate currents can be as high as 1 amp.

MOSFETs are capable of switching large amounts of current in incredibly short times. Their inputs are also relatively high impedance, which can lead to stability problems. Under certain conditions high voltage MOSFET devices can oscillate at very high frequencies due to stray inductance and capacitance in the surrounding circuit. (Frequencies usually in the low MHz.) This behaviour is highly undesirable since it occurs due to linear operation, and represents a high dissipation condition.

Spurious oscillation can be prevented by minimising stray inductance and capacitance around the MOSFETs. A low impedance gate-drive circuit should also be used to prevent stray signals from coupling to the gate of the device.

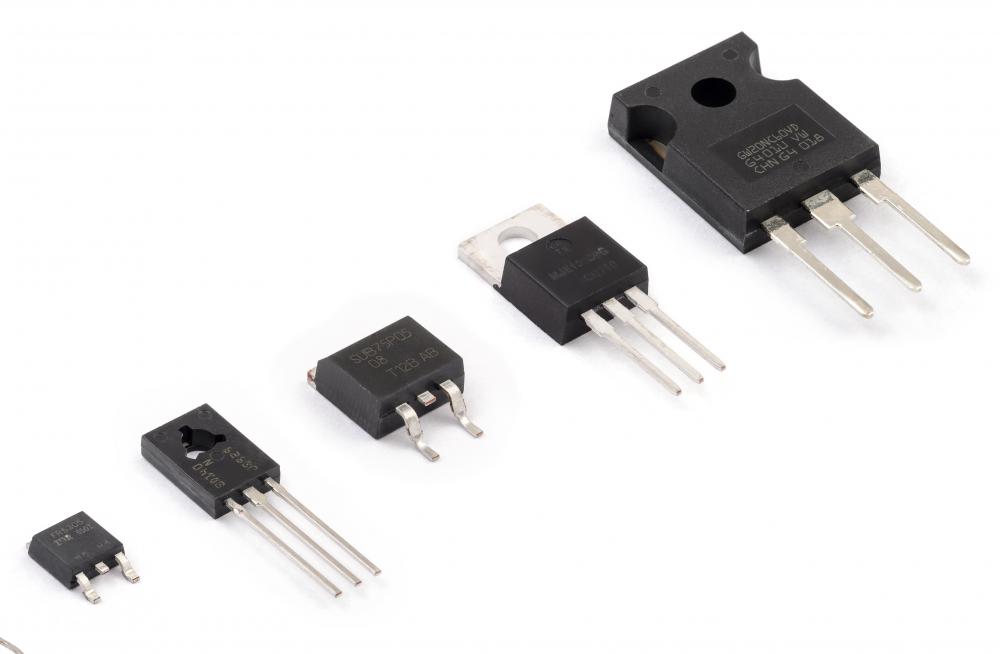

Most Common Mosfet

MOSFET devices have considerable 'Miller capacitance' between their gate and drain terminals. In low voltage or slow switching applications this gate-drain capacitance is rarely a concern, however it can cause problems when high voltages are switched quickly.

A potential problem occurs when the drain voltage of the bottom device rises very quickly due to turn on of the top MOSFET. This high rate of rise of voltage couples capacitively to the gate of the MOSFET via the Miller capacitance. This can cause the gate voltage of the MOSFET to rise resulting in turn on of this device as well ! A shoot-through condition exists and MOSFET failure is certain if not immediate.

The Miller effect can be minimised by using a low impedance gate drive which clamps the gate voltage to 0 volts when in the off state. This reduces the effect of any spikes coupled from the drain. Further protection can be gained by applying a negative voltage to the gate during the off state. eg. applying -10 volts to the gate would require over 12 volts of noise in order to risk turning on a MOSFET that is meant to be turned off !

- Conducted interference with controller:

Most Common Logic Level Mosfet

Rapid switching of large currents can cause voltage dips and transient spikes on the power supply rails. If one or more supply rails are common to the power and control electronics, then interference can be conducted to the control circuitry.

Good decoupling, and star-point earthing are techniques which should be employed to reduce the effects of conducted interference. The author has also found transformer coupling to drive the MOSFETs very effective at preventing electrical noise from being conducted back to the controller.

- Static electricity damage:

Mosfet Common Drain Amplifier

Antistatic handling precautions should be used to prevent gate oxide damage when installing MOSFET or IGBT devices. But are very reliable once they are soldered in place.

There are many more fact and circuits using MOSFETs on the web. This discussion is only a starting-point.